-

Empty cart

No products in the cart.

Return to Shop

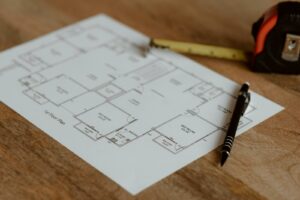

Introduction to Plan Printing

Whether you’re an architect finalising a building design, an engineer creating technical schematics, or a construction manager overseeing a project, high-quality printed plans are essential for clear communication and successful project execution. In today’s digital world, printing plans remain a critical component of many professional workflows.

What Are Plans and Why Print Them?

Plans are detailed technical drawings that visually communicate designs, specifications, and measurements for construction, engineering, or architectural projects. While digital files offer convenience for design work, printed plans provide numerous advantages:

- Tactile review: Physical plans allow for intuitive markup, annotation, and collaborative review

- On-site durability: Printed plans can withstand job site conditions

- Scale verification: Physical prints enable accurate measurement verification

- No technology requirements: Access doesn’t depend on devices, software, or battery life

- Legal documentation: Many jurisdictions still require physical copies for permits and approvals

Types of Printed Plans

The construction and design industries utilise several types of printed plans:

- Architectural plans: Building layouts, elevations, and detailed drawings

- Engineering plans: Structural, mechanical, electrical, and plumbing designs

- Construction documents: Comprehensive sets including specifications and details

- Shop drawings: Detailed fabrication instructions for specific components

- Site plans: Property layouts showing terrain, utilities, and landscape features

- As-built drawings: Final documentation showing completed construction

Common Use Cases

Plan printing serves diverse needs across multiple industries:

- Construction sites: Reference documents for builders and contractors

- Client presentations: Visual aids for project stakeholders

- Permit applications: Documentation for regulatory approvals

- Bid packages: Information for contractor pricing and proposals

- Design reviews: Collaborative markup and revision sessions

- Educational purposes: Teaching materials for technical courses

- Trade shows: Visual displays of company capabilities

Printing Methods and Technologies

The evolution of printing technology has transformed how plans are reproduced, with several methods available depending on your needs and budget.

Digital Printing

Modern manufacturing equipment in a futuristic factory is generated by artificial intelligence

Modern digital printing has largely replaced traditional methods, offering:

- Rapid turnaround: Same-day or next-day service for most projects

- Consistent quality: Reliable reproduction of fine lines and details

- Colour accuracy: Precise matching of specified colours

- Economical short runs: Cost-effective for small quantities

- Environmental benefits: Reduced chemical usage compared to traditional methods

Digital printing for plans typically uses one of two technologies:

- Inkjet: Sprays tiny droplets of ink onto media, excellent for colour renderings and presentations

- Toner-based: Uses electrostatic charges to apply toner, ideal for crisp line work and text

Large Format Printing

Modern printing press produces multi colored printouts accurately generated by artificial intelligence

For plans larger than standard office paper, large-format printers (often called wide-format printers) are essential:

- Size capability: Can handle media up to 60″ wide or more

- Roll-to-roll printing: Efficient for producing multiple consecutive sheets

- Cut-sheet options: Precise sizing for standard dimensions

- Material versatility: Works with various paper weights and speciality media

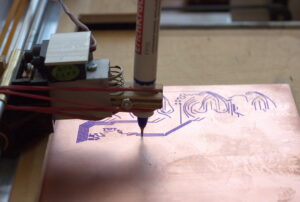

Plotter Printing

While “plotter” originally referred to vector-based drawing machines, today’s plotters are specialised large-format printers optimised for technical documents:

- Line quality: Exceptional reproduction of fine lines and text

- Speed efficiency: Optimised for monochrome or limited-colour technical drawings

- Precision: Accurate reproduction of scaled dimensions

- Media handling: Designed for construction document sets

Traditional Blueprinting

Though largely historical, traditional blueprinting (which produces white lines on a blue background) has been replaced by:

- Diazo printing: Chemical process creating blue-line prints (white background with blue lines)

- Xerographic methods: Photocopier-based reproduction

- Digital alternatives: Modern printing that mimics traditional appearance when needed

Choosing the Right Print Service

Selecting the appropriate printing solution depends on your specific requirements, budget, and timeline.

Professional Print Shops

Specialised print shops like Eco2Office offer comprehensive services:

- Expertise: Guidance on material selection and finishing options

- Quality control: Professional oversight of colour accuracy and detail reproduction

- Advanced equipment: Industrial-grade printers for optimal results

- Consistency: Reliable reproduction across multiple print runs

- Material options: Extensive selection of papers and speciality media

- Additional services: Collating, binding, and finishing capabilities

Online Services

Remote printing services provide convenience with some tradeoffs:

- Convenience: Upload files and receive shipments without leaving your office

- Competitive pricing: Often lower costs due to centralised production

- Limited consultation: Less personalised guidance on technical requirements

- Shipping considerations: Delivery time and potential damage during transit

- Quality variables: Difficult to verify quality until after delivery

In-House Printing Options

Maintaining printing capabilities within your organisation offers:

- Immediate availability: On-demand printing when needed

- Confidentiality: Sensitive documents remain internal

- Initial investment: Equipment purchase requires a substantial upfront cost

- Ongoing expenses: Maintenance, supplies, and technical support

- Space requirements: Large-format equipment needs a dedicated area

- Staff training: Team members need technical knowledge for quality results

Cost Comparisons

Understanding the financial implications of different printing approaches:

| Printing Method | Advantages | Disadvantages | Typical Cost Range (per sq. ft.) |

| Professional Print Shop | High quality, expertise, material options | Requires planning ahead | $0.75-$5.00 |

| Online Services | Convenient, often less expensive | Shipping delays, quality variations | $0.60-$4.50 |

| In-House Printing | Immediate access, control | Equipment investment, maintenance | $0.50-$3.00 (after equipment investment) |

File Preparation and Specifications

Proper file preparation ensures high-quality printed plans and efficient production.

File Formats

Common formats for plan printing include:

- PDF (Portable Document Format): Universal standard, preserves fonts and formatting

- DWG/DXF (AutoCAD formats): Native technical drawing files

- PLT (HPGL/2): Specialised plotter language for technical drawings

- TIFF: Raster format suitable for image-heavy designs

- JPG: Compressed format, acceptable for less detailed plans

Best practices for file preparation:

- Convert fonts to outlines or embed them in the document

- Include crop marks if specific trimming is required

- Maintain a consistent scale throughout the document

- Use PDF/X-1a:2001 standard for optimal printing compatibility

Resolution Requirements

Appropriate resolution ensures crisp, legible plans:

- Line drawings: Minimum 600 DPI for clear text and line work

- Renderings: 300 DPI for colour images and visualisations

- Mixed content: Higher resolution for areas with fine details

Colour vs. Black & White

Choosing between colour and monochrome printing:

- Black & white: Cost-effective for technical drawings, construction documents, and working copies

- Colour: Beneficial for presentations, renderings, and drawings with colour-coded elements

- Grayscale: Middle-ground option showing shading without full colour

Tips for optimising colour in technical drawings:

- Use consistent colour coding for systems (electrical, plumbing, etc.)

- Ensure sufficient contrast between elements

- Test print small sections to verify colour accuracy

- Consider how colours will translate to grayscale if copies will be made

Scale Considerations

Maintaining an accurate scale is critical for technical documents:

- Common scales: 1/4″ = 1′, 1/8″ = 1′, 1:100, 1:50, 1:20

- Scale bars: Include visual scale indicators on all sheets

- Verification method: Print test pages with measurement guides before full production

- Clear labelling: Note scale prominently on each sheet

Paper Types and Sizes

Selecting appropriate media enhances durability, appearance, and functionality.

Standard Sizes

Common plan sizes in North America:

- ANSI A (Letter): 8.5″ × 11″

- ANSI B (Tabloid/Ledger): 11″ × 17″

- ANSI C: 17″ × 22″

- ANSI D: 22″ × 34″

- ANSI E: 34″ × 44″

International standard sizes:

- A4: 210mm × 297mm (8.27″ × 11.69″)

- A3: 297mm × 420mm (11.69″ × 16.54″)

- A2: 420mm × 594mm (16.54″ × 23.39″)

- A1: 594mm × 841mm (23.39″ × 33.11″)

- A0: 841mm × 1189mm (33.11″ × 46.81″)

Custom sizes are also available from most professional print shops.

Paper Weights and Finishes

Paper weight options for plans:

- 20-24 lb bond/60-90 gsm: Economy option for working copies

- 28-32 lb bond/105-120 gsm: Standard weight for most construction documents

- 36-40 lb bond/135-150 gsm: Heavier stock for durability and presentation

- 60+ lb cover/160+ gsm: Rigid presentation-quality material

Surface finishes affect both appearance and functionality:

- Uncoated: Accepts written notes and markups, standard for working documents

- Coated: Enhanced image quality, better for presentations and renderings

- Satin/matte: Reduced glare, good compromise between image quality and markup ability

Specialty Materials

Beyond standard paper, consider:

- Vellum: Translucent material for overlays and light table use

- Mylar/polyester film: Extremely durable, water-resistant material for field use

- Adhesive-backed: Self-adhesive options for posting on job sites

- Synthetic papers: Tear-resistant and waterproof alternatives

Durability Considerations

For plans that will see active use:

- Lamination: Protective plastic coating (prevents markup)

- Encapsulation: Sealed edge lamination for maximum protection

- Mounting: Adhering to foam board or other rigid backing

- Reinforcement: Edge protection for frequently handled documents

Cost-Saving Strategies

Optimise your budget while maintaining quality with these approaches.

Bulk Printing Options

Volume-based savings:

- Set printing: Print complete document sets rather than individual sheets

- Quantity discounts: Most print shops offer reduced rates for higher quantities

- Standardisation: Use consistent sheet sizes throughout projects

Digital vs. Physical Storage

Balance between digital and physical documents:

- Limited printing: Print only the necessary sheets for specific tasks

- On-demand production: Store master files digitally, printing as needed

- Hybrid approach: Maintain digital archives with select physical copies

- Cloud storage: Secure off-site backup of all digital plan files

File Optimisation Tips

Prepare files to minimise printing costs:

- Nesting: Arrange multiple small drawings on a single sheet

- Line weights: Optimise for clarity with minimum ink usage

- Monochrome conversion: Convert colour elements to grayscale when colour isn’t necessary

- Compression: Reduce file size without compromising quality

Timing Your Prints

Strategic scheduling can reduce expenses:

- Avoid rush charges: Plan ahead for standard turnaround times

- Consolidated orders: Combine multiple projects into a single print order

- Off-peak pricing: Some shops offer discounts during slower periods

- Phased printing: Print only what’s needed for the current project phase

Best Practices for Successful Plan Printing

Maximise quality and efficiency with these industry-tested approaches.

Quality Control Checklist

Before submitting files for printing:

- Proofread: Check all text for errors and consistency

- Scale verification: Confirm accurate dimensions and scale indicators

- Layer management: Ensure appropriate layers are visible/printable

- Line weights: Verify distinction between different line types

- Font embedding: Confirm all fonts are embedded or converted to outlines

- Border/margin check: Allow sufficient white space around content

- Resolution verification: Ensure all embedded images meet resolution requirements

Working With Print Professionals

Maximise service quality:

- Clear communication: Provide detailed specifications and requirements

- Sample prints: Request samples of similar projects before large orders

- File delivery: Follow recommended file submission protocols

- Proofing options: Request digital or physical proofs for critical projects

- Pickup preparation: Confirm packaging requirements for large-format prints

Sustainable Printing Options

Environmentally responsible choices:

- Recycled paper: Many options now offer excellent print quality

- FSC certification: Paper from responsibly managed forests

- Reduced chemical processes: Modern digital printing minimises chemical usage

- Print optimisation: Only print necessary sheets at appropriate quantities

- Digital distribution: Share PDF versions when physical copies aren’t required

Turnaround Times

Typical industry timeframes:

- Standard service: 1-2 business days for most projects

- Rush service: Same-day or next-day options (higher cost)

- High-volume projects: 3-5 business days for large sets

- Speciality materials: May require additional production time

At Eco2Office, our blueprint and site plan printing services ensure precision and clarity for every project with competitive turnaround times.

Conclusion

Effective plan printing remains a critical component of successful architecture, engineering, and construction projects. By understanding the available technologies, materials, and best practices, professionals can ensure their technical documents serve their intended purpose while managing costs effectively.

Whether you’re preparing construction documents, design presentations, or permit applications, choosing the right printing approach makes a significant difference in both the quality of your documentation and the efficiency of your workflow.

For precision blueprint and site plan printing services that ensure clarity and accuracy for every project, contact Eco2Office at 832-437-3204 or visit us at 403 W Grand Pkwy S, Suite F, Katy, TX 77494.

FAQ: Common Questions About Plan Printing

Q: How much does it typically cost to print construction plans?

A: Costs vary based on size, quantity, and material, but typical ranges are $0.75-$5.00 per square foot for professional printing. A standard 24″x36″ plan might range from $3-$15 per sheet, depending on paper quality and other specifications.

Q: What’s the difference between bond paper and vellum for plans?

A: Bond paper is opaque, more economical, and suitable for most working copies and final documentation. Vellum is translucent, allowing for overlays and use on light tables, but typically costs 30-40% more than comparable bond paper.

Q: How long does it take to print a complete set of construction documents?

A: Small sets (up to 20 sheets) can typically be completed in 1 business day. Larger sets may require 2-3 business days. Rush services are available at many print shops, including Eco2Office, for same-day or next-day completion.

Q: Can I print plans directly from my CAD software, or should I convert to PDF first?

A: While direct printing is possible, converting to PDF first provides better control over the final output and reduces potential compatibility issues. PDFS also allow for easier proofing before submission.

Q: What’s the best way to transport large printed plans?

A: For maximum protection, transport plans in dedicated tubes or flat in portfolio cases. Most professional print shops offer tubes or protective wrapping for large-format prints.

Ready to optimise your plan printing process? Contact Eco2Office today for a consultation on your specific project needs and discover how our expertise can enhance your technical documentation while keeping costs manageable. Request a quote online or call 832-437-3204 to speak with our technical printing specialists.